Request Quote

Home | Our Blog | Different Types of Flat Roof Material Options - Which is Best?

Reviewed by Tomas Kalkys. President.

Qualifications: More than 20 years of experience in residential and commercial exterior remodeling.

Founding farther of Legacy Service.

Written by LegacyUSA Team

posted on Nov 15, 2019

Get Estimates From Roofing Pros

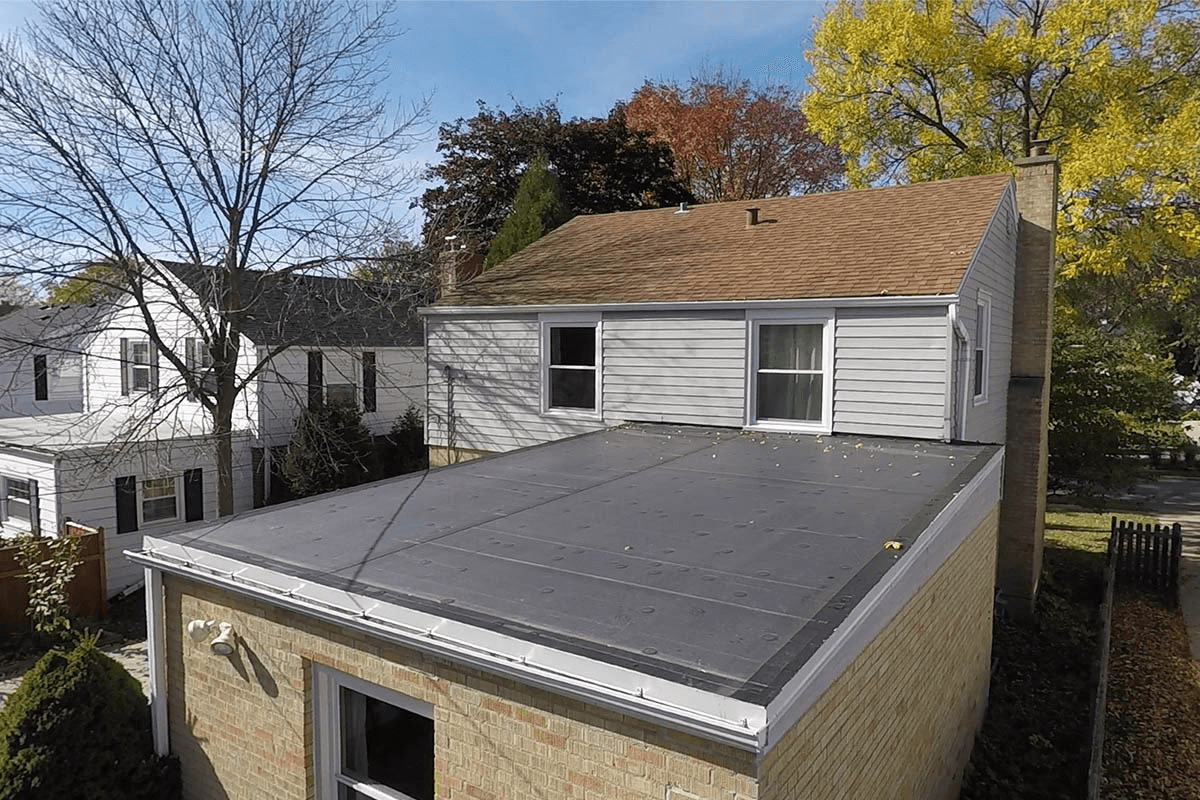

There are two basic types of covering for roofs: pitched and flat horizontal. Flat coverings were initially spread mainly in the southern Mediterranean and Asian countries, and pitched ones were found in countries of northern Europe.

The explanation for this is quite simple: The covering should provide reliable house waterproofing and withstand the accumulating loads. This problem is not so acute in sunny southern countries; there, people usually choose the cheapest option of covering the building. In the northern countries, a pitched roof is a necessary option, albeit more expensive when constructing.

Until recently, flat roofs have been designed only for industrial facilities or multi-story residential houses, while traditional gable, mansard, or hip types have been constructed for low-rise buildings. But the technology and improvement of building components’ market have made it possible to use horizontal coverings in individual housing development.

Not a real zip code.

With a private house or cottage, it’s not hard to build a second and even third floor instead of the attic, and place a sports room, resting place, or a small greenhouse in the additional area. All of this contributes to the growing flat construction popularity, while modern technologies and building materials make it possible to not only reduce residential house building costs but also provide it with significant reliability and durability.

Pros for main flat coverings include their simplicity and cheapness. If the price of arranging a pitched roof is about 20–25%, and sometimes even 50%, of the total cost, then investments in flat roofing materials will be mainly determined by the costs of strengthening the upper floor.

The components used for horizontal coverings should provide high-quality waterproofing for the entire structure. Nowadays, materials used for flat roofs must have these requirements:

Flat coverings consist of a collection of materials that provide reliable house waterproofing and maintain an optimal microclimate. These include:

In such a way, traditional paper, cardboard, and bitumen roofing products are inferior to modern components in all respects.

There are three basic types:

The polymer membrane has become more and more widespread in building coverings’ repair and decoration areas, and it’s in demand in the USA, Canada, and Europe. Membrane roofs’ popularity is explained by their high reliability, rich color palette, good adaptability to different temperatures (whether low or high) and durability (life span up to 40 years).

EPDM is the latest technology (+/- 55 years), while BUR is the oldest one (+/- 120 years).

EPDM rubber covering is made from environmentally-friendly recycled rubber materials. In addition to pure EPDMs with a rubber base, composite flat roof replacement materials are also available. Their upper layer is traditionally rubber, while the lower one is flexible bitumen-polymer.

EPDM rubber covering prices vary from $4 to $8 per square foot.

Not a real zip code.

PVC Membranes are innovative waterproofing flat roof materials. PVC roofs are a single-layer type based on elastic polyvinyl chloride (PVC-P). Hot air welding provides it with absolute imperviousness.

Installing a PVC membrane costs about $7 to $11 per square foot.

Built-up roof (BUR) uses tar and gravel to create a waterproof layer over the covering. This is one of the most costly types of roofing materials for a residential building. Here are the pros and cons:

The cost varies from $5 to $8 per square foot.

For 60 years, BUR has been the only option. Then, in the early 1960s, a new technology called Modified Bitumen was introduced. This type of covering has reinforced the proven effectiveness of BUR, but also added layers for strength and durability.

The price can range from $3 to $6 per square foot.

It may not seem the safest or the most effective coating, but it is one of the most expensive types of roofing. This method uses a coating to repel water and has one important advantage: there are no seams here.

Price varies from $3 to $6 per square foot.

It’s advised to use this type on the construction of complex buildings, in particular – buildings of industrial and social purpose including enterprise workshops, administrative buildings, sports facilities, hotels, recreation centers, cafes, and restaurants.

The cost ranges from approximately $5 to $8.50 per square foot.

The use of top-notch roofing materials and technologies will make it possible to get away from the standard design, as well as to diversify individual solutions and options.

A variety of materials can be used to make a flat roof. The most common ones include EPDM rubber, single-ply (TPO, PVC), modified bitumen, built-up roofs (BUR), and spray polyurethane foam. Many homeowners choose either EPDM or TPO. EPDM roofs are affordable and can reach a lifespan of 30+ years. TPO roofs are easy to install and maintain, and their white color can help reflect heat from the sun and improve a building’s energy efficiency.

EPDM is the most popular material to use for flat roofs—and for good reason! Not only is it one of the most affordable materials, but it also has a respectable lifespan. Since it uses polymer and synthetic rubber, it provides the roof with excellent flexibility and elasticity. TPO is another popular flat roof material. It’s affordable, easy-to-install, and its white color helps improve a building’s energy efficiency.

EPDM, or Ethylene Propylene Diene Monomer, is known as the longest-lasting flat roof material. It’s designed to withstand the most extreme weather conditions that a flat roof can face, and this durability can help it last at least 30 to 50 years. If you’re seeking a long-lasting flat roof that’s permanently flexible and highly resistant to UV and infrared light as well as acids from rainwater, then EPDM may be the roof for you.

Yes, zinc roofs can be used on very low pitches. In some cases, the slope can be as low as 3° depending on the type of jointing seam used. Zinc roofs are laid in bays, much like lead, and usually with standing seam joints. These types of roofs can last up to 50 years or more.

In most cases, rubber roofs are considered superior to traditional felt roofs due to the broad range of benefits they offer. EPDM and TPO are two of the most popular types of rubber roofing. Not only are they easy to install, but they’re also among the highest quality materials available for flat roofs. Contact our team of professionals if you’re interested in installing or replacing your flat roof.

Learn more about flat roof replacement services by calling Legacy Service at +1 267-961-7088

Posted on Nov 15, 2019 in Roof

Read our news

HOW LONG SHOULD A ROOF LAST? ELEMENTS

A lot of elements play a role in maintaining the integrity of the roof, but as a homeowner, the most important components to pay attention to are the underlayment, ventilation, and material.

DIFFERENT TYPES - DIFFERENT LIVES

Choosing the best roofing material for your home is the first important step in ensuring that you have the highest quality roof possible.

METAL ROOF VS ASPHALT SHINGLE ROOFING

Two of the most popular roofing materials on the market are metal and asphalt, and both offer different pros and cons to a customer.

Pros and cons of Asphalt Shingle Roofing

Replacing a roof is an expensive decision, and cannot only come down to cost.